We prepare the Eternit-plates for the bottom, the walls and the roof. The plates had been cut exactly the right size by the specialist shop.

As shown people screw the bottom plate on the scantlings which also will be screwed and sticked with the rising boards.

The glue will be applied on the scantlings in order to screw on the front wall later.

The front wall has been fitted and the case will be prepared for the roof’s assembly.

On the roof plate of the completely prepared case we fix the bituminous roofing felt using a propane gas burner. This materials protects the case from rain and offers to the kestrels a safe seat they will not slip from.

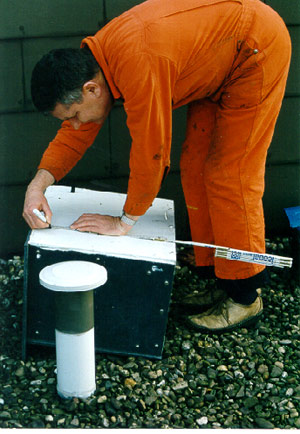

I by myself select the points for the drillings on the rear side wall. I pass through these holes the screws which will fasten together with dowels our case on the wall.

The case hangs on the wall and I cover the bottom by beech wood chaff as thick as a finger. The female kestrel has to be able to claw a breeding hollow for her eggs! Theses birds never prepare her own nest!

And so looks a completely assembled case. The beech wood chaff has been applied and the bottom drillings has been finished;

so the rain water seeping into the case would run outside though the bottom drillings. Very well people will realize the wall plates which overlaps about 5 mm the outside of the bottom plate and the square beams. No we are waiting for the kestrels only!